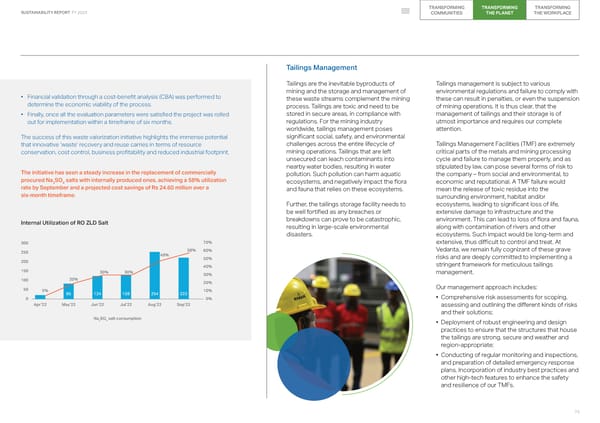

TRANSFORMING TRANSFORMING TRANSFORMING SUSTAINABILITY REPORT FY 2023 COMMUNITIES THE PLANET THE WORKPLACE Tailings Management Tailings are the inevitable byproducts of Tailings management is subject to various mining and the storage and management of environmental regulations and failure to comply with • Financial validation through a cost-benefit analysis (CBA) was performed to these waste streams complement the mining these can result in penalties, or even the suspension determine the economic viability of the process. process. Tailings are toxic and need to be of mining operations. It is thus clear, that the stored in secure areas, in compliance with management of tailings and their storage is of • Finally, once all the evaluation parameters were satisfied the project was rolled out for implementation within a timeframe of six months. regulations. For the mining industry utmost importance and requires our complete worldwide, tailings management poses attention. The success of this waste valorization initiative highlights the immense potential significant social, safety, and environmental that innovative ‘waste’ recovery and reuse carries in terms of resource challenges across the entire lifecycle of Tailings Management Facilities (TMF) are extremely conservation, cost control, business profitability and reduced industrial footprint. mining operations. Tailings that are left critical parts of the metals and mining processing unsecured can leach contaminants into cycle and failure to manage them properly, and as nearby water bodies, resulting in water stipulated by law, can pose several forms of risk to The initiative has seen a steady increase in the replacement of commercially pollution. Such pollution can harm aquatic the company – from social and environmental, to procured Na SO salts with internally produced ones, achieving a 58% utilization ecosystems, and negatively impact the flora economic and reputational. A TMF failure would 2 4 rate by September and a projected cost savings of Rs 24.60 million over a and fauna that relies on these ecosystems. mean the release of toxic residue into the six-month timeframe. surrounding environment, habitat and/or Further, the tailings storage facility needs to ecosystems, leading to significant loss of life, be well fortified as any breaches or extensive damage to infrastructure and the Internal Utilization of RO ZLD Salt breakdowns can prove to be catastrophic, environment. This can lead to loss of flora and fauna, resulting in large-scale environmental along with contamination of rivers and other disasters. ecosystems. Such impact would be long-term and 300 70% extensive, thus difficult to control and treat. At 250 58% 60% Vedanta, we remain fully cognizant of these grave 48% 50% risks and are deeply committed to implementing a 200 stringent framework for meticulous tailings 40% 150 30% 30% management. 30% 100 20% 20% 50 5% 10% Our management approach includes: 85 124 128 254 222 0 0% • Comprehensive risk assessments for scoping, Apr’22 May’22 Jun’22 Jul’22 Aug’22 Sep’22 assessing and outlining the different kinds of risks and their solutions; Na SO salt consumption 2 4 • Deployment of robust engineering and design practices to ensure that the structures that house the tailings are strong, secure and weather and region-appropriate; • Conducting of regular monitoring and inspections, and preparation of detailed emergency response plans. Incorporation of industry best practices and other high-tech features to enhance the safety and resilience of our TMFs. 73

2023 ESG Report Page 72 Page 74

2023 ESG Report Page 72 Page 74