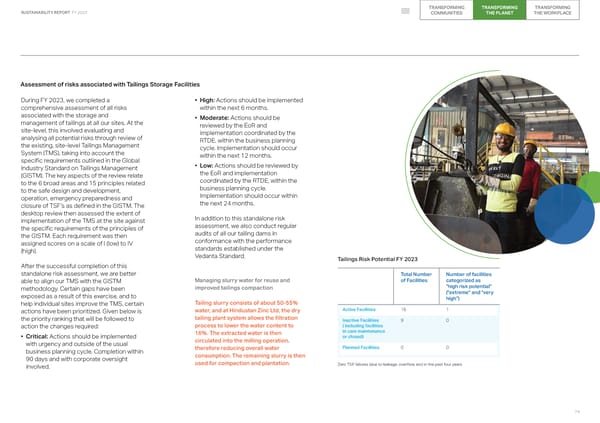

TRANSFORMING TRANSFORMING TRANSFORMING SUSTAINABILITY REPORT FY 2023 COMMUNITIES THE PLANET THE WORKPLACE Assessment of risks associated with Tailings Storage Facilities During FY 2023, we completed a • High: Actions should be implemented comprehensive assessment of all risks within the next 6 months. associated with the storage and • Moderate: Actions should be management of tailings at all our sites. At the reviewed by the EoR and site-level, this involved evaluating and implementation coordinated by the analysing all potential risks through review of RTDE, within the business planning the existing, site-level Tailings Management cycle. Implementation should occur System (TMS), taking into account the within the next 12 months. specific requirements outlined in the Global • Low: Actions should be reviewed by Industry Standard on Tailings Management the EoR and implementation (GISTM). The key aspects of the review relate coordinated by the RTDE, within the to the 6 broad areas and 15 principles related business planning cycle. to the safe design and development, Implementation should occur within operation, emergency preparedness and the next 24 months. closure of TSF’s as defined in the GISTM. The desktop review then assessed the extent of In addition to this standalone risk implementation of the TMS at the site against assessment, we also conduct regular the specific requirements of the principles of audits of all our tailing dams in the GISTM. Each requirement was then conformance with the performance assigned scores on a scale of I (low) to IV standards established under the (high). Vedanta Standard. Tailings Risk Potential FY 2023 After the successful completion of this standalone risk assessment, we are better Total Number Number of facilities Managing slurry water for reuse and of Facilities categorized as able to align our TMS with the GISTM methodology. Certain gaps have been improved tailings compaction "high risk potential" exposed as a result of this exercise, and to ("extreme" and "very Tailing slurry consists of about 50-55% high") help individual sites improve the TMS, certain water, and at Hindustan Zinc Ltd, the dry Active Facilities 16 1 actions have been prioritized. Given below is the priority ranking that will be followed to tailing plant system allows the filtration Inactive Facilities 9 0 action the changes required: process to lower the water content to ( including facilities 16%. The extracted water is then in care maintenance • Critical: Actions should be implemented circulated into the milling operation, or closed) with urgency and outside of the usual therefore reducing overall water Planned Facilities 0 0 business planning cycle. Completion within consumption. The remaining slurry is then 90 days and with corporate oversight used for compaction and plantation. involved. Zero TSF failures (due to leakage, overflow, etc) in the past four years 74

2023 ESG Report Page 73 Page 75

2023 ESG Report Page 73 Page 75